Part-3: Battery Tester based on Microcontroller

Construction of battery health Monitor and battery desulfator:

As it has been explained in previous two posts and the name of project also describes that the actual project has two main parts and associated functions.

1. Battery Heath Monitor

2. Desulfator

Now we will discuss its construction in detail. This project is constructed using microcontroller PIC18452. It has been programmed and the code of the project has been written in basic language and compiled using proton PIC basic complier. The program or code listing is provided in the end of this post.

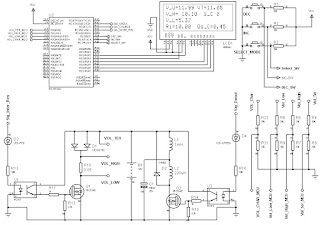

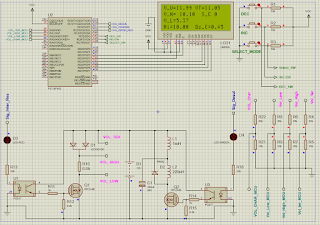

Circuit diagram of the microcontroller based two in one project of battery performance monitor or tester and desulphator is as below.

|

| Circuit diagram of Microcontroller based battery internal resistance Monitor |

There are Four Segments of the schematic shown in above figure:

1. The Interface of Microcontroller with LCD

2. For adjustment of parameters, the provision of three input push button

3. The measurement of voltages at various stages of project during operation

4. Power module of battery tester which is again consisting of two parts:

(a) The battery Tester side, which left side of power module section

(b) The desulfator power section which is at the right side of power module

These will be discuss one by one in detail in below sub-section of this post. Various components used in each section will be introduced and their functionality will be explained as under.

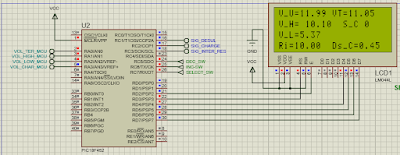

Microcontroller Project Schematic Part-1: 18f452 interfacing with 4-lines 20-Character LCD:

In the first part of whole schematic of this microcontroller project, we will discuss the interfacing of LCD with the PIC Microcontroller which is 18F452. The LCD we are using here in this battery tester cum desulphator is a large LCD which is consisting of Four Lines and each line will have twenty Character spacing. The various parameter will be display at different lines of LCD using microcontroller. The alpha-numeric LCD is interfacing using standard four line interface method as shown in the figure below:

Microcontroller interfacing LCD for Battery Tester Project

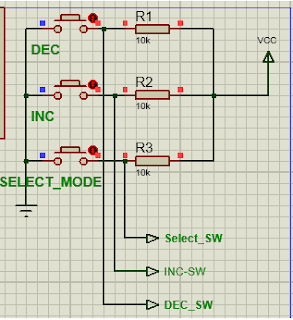

Microcontroller Project Schematic Part-2: 18f452 interfacing with Three Push Buttons:

Three push button have been provided to user for the adjustment of values of critical parameters to be adjusted according to the needs of user real time. These Push buttons are as under:

1. The Setting Selection Mode Switch

2. To increase the parameter values, the ICREMENT Button

3. To decrease the parameter values, the DECREMENT Button

The push switches are pull-up with 10kohm resistors and when press the logic zero is transmitted to microcontroller which is sensed during key-button scanning and the function is performed as per request of user of battery tester at that time, as shown in figure below:

|

| Three push button with 18F452 PIC Microcontroller |

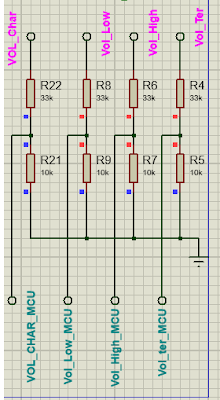

Microcontroller Project Schematic Part-3: Analog Voltages Measurement Interface to Microcontroller:

As the battery Attached for testing may have voltage 6V, or 12V, or 24V which are larger to be interface with microcontroller which accept voltage up to 5v. Therefore voltage divider is used as shown in the figure below: Two resistor are used one is 33Kohm and second is 10Kohm which divide the 12V divided by a factor of approximately 3.3 which is in acceptable range. If user have to interface larger battery the values of above resistor can be re-adjusted and factor used in program as well.

|

| Voltage Divider Circuit Diagram |

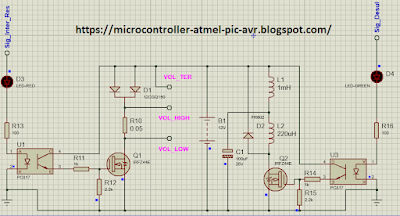

Microcontroller Project Schematic Part-4: Power Module of Battery Tester and Battery Desulfator:

The N-Channel MOSFET Transistor , shunt resistor of 0.05Ohm, is used in Battery Tester side. Whereas The N-Channel MOSFET Transistor, two inductors, diode, capacitor is used in desulphator side of power module as shown in figure below. The battery is at the center of these two type of interfaces. It may be noted that only one function is performed at a time. It means that when we are measuring the internal resistance, the desulfator part is turned off. At an other time when the desulfation of battery is in progress the measurement of internal resistance is switched off. So that each function is performed independently without interference to each other. In this way the results are achieved perfectly.

|

| Battery Tester CUM battery Desulfator |

Complete circuit diagram of the battery tester project:

|

| Battery Tester Complete Schematic Circuit Diagram using PIC Microcontroller |

Programming of Battery Tester:

The program is written in PIC Basic Language and compile using proton basic compiler, the code listing is provided as under:

Device = 18F452 Declare Xtal = 4 Config_Start OSC = HS ' Oscillator Selection HS OSCS = Off ' Osc. Switch Enable Disabled PWRT = On ' Power-up Timer Enabled BOR = Off ' Brown-out Reset Disabled BORV = 42 ' Brown-out Voltage 4.2v WDT = Off ' Watchdog Timer Disabled WDTPS = 128 ' Watchdog Postscaler 1:128 CCP2MUX = On ' CCP2 MUX Enable (RC1) STVR = On ' Stack Overflow Reset enabled LVP = Off ' Low Voltage ICSP Disabled Debug = Off ' Background Debugger Enable Disabled CP0 = Off ' Code Protection Block 0 Disabled CP1 = Off ' Code Protection Block 1 Disabled CP2 = Off ' Code Protection Block 2 Disabled CP3 = Off ' Code Protection Block 3 Disabled CPB = Off ' Boot Block Code Protection Disabled CPD = Off ' Data EEPROM Code Protection Disabled WRT0 = Off ' Write Protection Block 0 Disabled WRT1 = Off ' Write Protection Block 1Disabled WRT2 = Off ' Write Protection Block 2 Disabled WRT3 = Off ' Write Protection Block 3 Disabled WRTB = Off ' Boot Block Write Protection Disabled WRTC = Off ' Configuration Register Write Protection Disabled WRTD = Off ' Data EEPROM Write Protection Disabled EBTR0 = Off ' Table Read Protection Block 0 Disabled EBTR1 = Off ' Table Read Protection Block 1 Disabled EBTR2 = Off ' Table Read Protection Block 2 Disabled EBTR3 = Off ' Table Read Protection Block 3 Disabled EBTRB = Off ' Boot Block Table Read Protection Disabled Config_End Declare LCD_DTPin = PORTD.4 Declare LCD_ENPin = PORTD.2 Declare LCD_RSPin = PORTD.3 Declare LCD_Interface = 4 ' 4-bit Interface Declare LCD_Lines = 4 ' 2-Line LCD Declare LCD_Type = 0 ' Alphanumeric LCD type Symbol I_R = PORTC.3 'DEC_SWITCH Symbol B1 = PORTC.5 ' Select_MODE_Switch Symbol B2 = PORTC.6 ' INC_SWITCH Symbol B3 = PORTC.7 'DEC_SWITCH TRISD = %00000000 'All OUTPUT TRISC = %11110000 '// 0 t0 3 output and 4 to 7 input Declare Adin_Tad = FRC ' Set clock source (x/FOSC or FRC) Declare Adin_Stime = 150 ' Set sampling time (in uS) Declare Adin_Res = 10 ADCON1 = %10000000 ' Set PORTA analog and right justify result Dim Vol_Un_LOAD As Word ' Volatge at termminal without load Dim Vol_Ter As Word ' 10-bit result of A/D conversion for Volatge at battery terminal Dim Vol_High As Word ' 10-bit result of A/D conversion for Voltage at high side of shunt resistor Dim Vol_Low As Word ' 10-bit result of A/D conversion For Voltage At low side of shunt resistor Dim Vol_Charge As Word ' 10-bit result of A/D conversion For Voltage At charging side of shunt resistor Dim R_inT As Float ' Internal Resistance measurement Dim Dis_C As Float ' Discharge current 'Dim Char_C As Float ' charging Current 'Dim d As Byte Dim mode_op As Byte ' The two mode of functions are selected by this variable Dim mode_0_count As Byte ' The times to function each paert of project Dim secondary_cycle_count As Byte ' Time slice Dim duty_cycle As Byte ' PWM DUTY CYCLE valraible Dim cycle_count As Byte ' Program CYCLE are counted and displayed on LCD I_R = 0 ' Internal Resistance measuremtn Signal OFF ''''' INITIAL WELLCOME MESSAGE''''''''' Print At 1,1, "Wellcome..DeSulfator" Print At 2,1, " Battery Project" Print At 3,1, "microcontroller-atmel-" Print At 4,1, "pic-avr.blogspot.com" DelayMS 1000 ' One Second Time delay Cls ' Clear The LCD DISPLAY ''' INITIALIZATION of LOCAL Variables mode_op = 0 secondary_cycle_count = 0 mode_0_count = 5 ' for a PIC16F877, 'Channel 1 is CCP1 which is pin PortC.2. 'Channel 2 is CCP2 which is pin PortC.1. ' Start loop, reads temperature. Loop forever '''''' Main program Starts here''''''''''' While 1 = 1 If cycle_count < mode_0_count Then '' The check the cycle for approprate functioning mode_op = 0 Else mode_op = 1 EndIf '''''Adjustment of testing time'''''' If B2 = 0 Then Inc mode_0_count If B3 = 0 Then Dec mode_0_count If mode_0_count <=1 Then mode_0_count = 1 If mode_0_count >=5 Then mode_0_count = 5 ''''''' Select SWITCH CASE for execution of each function one by one''''''' Select mode_op Case 0 ''''CASE 0 for the measurement of battery health by calculating the internal resistance Cls HPWM 2,0,8000 '' Turn OFF the PWM during measurement of internal resistance '''' The battery Voltages are being measured without any load''''' I_R = 0 '' MOSFET is OFF Vol_Un_LOAD = ADIn 0 ''' analog to digital conversion of un-load terminal voltage of battery DelayMS 100 I_R = 1 '' MOSFET is ON Vol_Ter = ADIn 0 ' Analog to Digital Conversion of Terminal Voltages of battery with load DelayMS 10 Vol_High = ADIn 1 ' Analog to Digital conversion of voltage at high side of shunt resistor DelayMS 10 Vol_Low = ADIn 2 ' Analog to Digital conversion of voltage at low side of shunt resistor DelayMS 10 I_R = 0 '' MOSFET is OFF ' The Internal resistance of battery will be calculated using following formula''''' ''''R_int = shunt * (Unload_V - Terminal_V)/ (High_V - Low_V) ''''' R_inT = 0.05 * (Vol_Un_LOAD - Vol_Ter) / (Vol_High - Vol_Low ) '''Current passed through the shunt resistor during load will be calculted using this''' Dis_C = R_inT * (Vol_Un_LOAD - Vol_Ter) ''' The results are displayed on LCD'''' Print At 1,1, "V_U=", Dec2 Vol_Un_LOAD* 0.02101 ," VT=", Dec2 Vol_Ter* 0.02101 Print At 2,1, "V_H= ", Dec2 Vol_High* 0.02101," S_C ", Dec cycle_count Print At 3,1, "V_L=", Dec2 Vol_Low* 0.02101 Print At 4,1, "Ri=", Dec2 R_inT * 1000, " Ds_C=", Dec2 Dis_C DelayMS 1000 ' wait for one second ''''The second function the desulfator starts in next case''''' Case 1 I_R = 0 '' The MOSFET for iternal resistance load side must be OFF Cls '' clear the display Print At 1,1, "mode = 2 " Print At 2,1, "desulfation started" Print At 3,1, "S-Cnt ", Dec cycle_count HPWM 2,duty_cycle,8000 '''' Generate PWM signal of 8kHz with 50% duty Cycle DelayMS 1000 'If duty_cycle >=254 Then duty_cycle = 10 Case Else Cls EndSelect Inc cycle_count If cycle_count >= 254 Then cycle_count = 0 Wend

No comments:

Post a Comment

Please ask if you have any question regarding the programming of MCU, or have any problem in development of your electronics project. microcontroller51.blogspot.com