Microcontroller for Industrial Automation

This project is related to provide a solution to control problem like the controlling of industrial machinery or home appliances remotely from a remote location. The main objectives of development the remote controller project is to evade human errors, accidents and to increase safety factors while provide prompt control. The 8051 Microcontroller is the heart of this project. The microcontroller based automation systems will detects some parameters from the environment where the machine or appliance is running without the human interact and sensed the report to user for appropriate actions. The parameters which could be sensed or checked using suitable sensors are such as Temperature, LPG Gas Smoke, fire, pressure etc. or any of user requirements. The home or industrial appliances control system will provide remote access through the use of mobile phone. Secured working of appliance or machinery is the basic wish of any holder of the machine. To work the machines safe way needs proper monitoring for crucial parameters of environment, so that an early decision could be implemented. Similarly the security of valuables, property machine and or factory is also a main concern around us. This project idea is established to provide both features to use for the development of safe and secure environment to the valuable property. As told earlier we will use the Microcontroller in this project as heart of project, as all important tasks will be processed here inside the microcontroller like acquiring the data from sensors, process the information, compare with the safe limits and if required transmit the message to owner or generate the alarm or buzzer. The Microcontroller is a complete computer system which is composed of microprocessor, limited ROM or EPROM, RAM, and I/O ports and all these parts built in a single integrated circuit (IC). The list of sensor propped to be used in this project will be as follows:

- Smoke sensor,

- gas sensor,

- LPG sensor,

- Temperature sensor,

- Pressure sensor,

- Humidity sensor,

- Fire detection sensor.

Lets briefly discussed why we proposed to use the Gas sensor because it can sense the leakage of liquid petroleum related gases very earlier then the system can intimate with alarm buzzer and very quickly the exhaust fan can be turned ON and lights or other related equipment can be switch OFF automatically and efficiently without the involvement of any human or even in the absence of any human body. The detection of such gases is very important in the industry as it can cause fire. Similarly the other sensors also play very vital role in the early detection of associated parameters and efficient control of appliance by the system like smoke sensor, Temperature and humidity sensor. The smoke sensor will detect smoke if it is present. The fire sensor is used to provide protection in the case of fire and it can be attached to control the water sprinkler system if available at the spot. The temperature measurement sensor is used to find out the temperature levels and to control the switching of fans or exhaust unit and heaters.

Description of the System

The Microcontroller will be interfaced with various sensor or detector as discussed earlier like Temperature transducer, Fire sensor, LPG detector and Smoke sensor. It may be noted that the terms sensor or detector or transducer will be used interchangeably in this post because we are considering all three same although of course these have slightly difference in their meanings, but to make it ease why may use it any of these through the post. The parameters will be continuously measured using above sensor and data will be acquired in microcontroller, the average values of instant signals will be calculated and it will be compared to the set point given to the microcontroller. If there is any abnormality is observed this situation will be taken as an accident or an emergency situation where appropriate measure are required to implement. Here in this automatic controller project the Atmel AT89S52 microcontroller is being used. This microcontroller is a reasonably powerful microcontroller having some nice advantages over the other like with cost effectiveness it can be used in many embedded control applications and it is serially programmable device. The embedded application uses microcontroller chip as central processing unit with various support functions like interfacing with other device through the use of input and output pins of ports of microcontroller. Standard Features of AT89S52 Microcontroller:

- It is Compatible with MCS-51 products, belongs to 8051 microcontroller family

- It has 8k bytes programmable flash memory

- We can attach crystal to it up to 33 MHz

- It has better program memory lock system consisting of three ways

- It has RAM consisting of 256 x 8-bit Internal

- Its operating range is 4.0 to 5.5V DC

- It has 32 programmable Input / Output lines over a four ports each is 8 bits.

- It has total 8 interrupts

- It has three 16-bit Timer or Counters built in.

Construction Plan of the project:

This project is mainly consisting of following two main parts:

- Detection and Protection system

- Load controlling system

In the detection and protection system various sensors are proposed to be used such as smoke detector, temperature detector sensor, LPG gas detector sensor, fire detector sensor etc. In the load controlling system, some device or equipment will be turned ON or OFF through the use of appropriate relays such as cooling fan, exhaust fans, water pump, tube lights, bulbs, alarms and buzzers etc. Each part of this project will be discussed in detail as below.

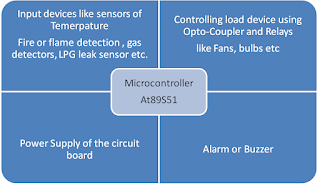

Block Diagram of the System:

Circuit Block diagram of automation of industry using microcontroller for the safe operation of machines and ensuring the safety of workers and equipment.

|

| Block Diagram of Automation Project for the safety and security of Industrial Equipment |

Smoke detector

Gas or smoke sensors are often used to detect and measure the concentration of toxic or explosive gasses in air. During a fire event a lot of gases and smoke is produced. If the flammable gases are available in the environment then conductivity of the sensor will be increased as a function of gas concentration in the atmosphere. In this project the MQ-2 Smoke sensor is used for the detection of smoke in the air. The advantage of selection and use of this sensor is that it is sensitive to smoke and as well as to flammable gas at the same time. The Output pin of the smoke sensor gives the voltage output proportionally to concentration of toxic gasses or the smoke or flammable gases exposed to this sensor. The sensing material used in the gas sensor (MQ-2) is the Tin-dioxide (SnO2). The conductivity of this gas sensing material is low in clean air but increases with the concentration of gases in air. The Output voltage of the sensor will boost along with the concentration of the toxic gases increases. The gas sensor (MQ-2) has a high sensitivity to Hydrogen, Propane and other liquefied petroleum gases. This sensor is also good for the detection of natural gas and other combustible vapors. The MQ-2 can detect a variety of flammable gases at a very low cost sensor therefore it is suitable for many of applications. The following are some important features of smoke sensor MQ-2.

- It has good fast response and fast recovery

- Easy interface able electronics circuit

- Sensitivity to gases can be adjusted

- Built in output signal indicator

- Operating Power range 2.5V to 5.0V DC

Electrical connection to Microcontroller:

Pin wise interface of smoke sensor to the Atmel at89s51 microcontroller is as under:

- VCC ↔ 2.5V ~ 5.0V

- GND ↔ power supply ground

- AOUT ↔ I/O of Microcontroller (analog output)

- DOUT ↔ I/O of Microcontroller (digital output)

LPG Gas Detector

The leakage of gases is a major problem in homes and industries. The LPG gas Detector is used in this project to detect the concentration of dangerous and ignitable gas due to leakages such as LPG, Town gas and natural gas. To preventive the accident due to leakages of gases required to install a gas leakage detector at vulnerable places. The gas leak detector is very important to ensure the safe handling, operation and consumption of combustible, toxic or hazardous gases like LPG. The gas detectors sniff out even very small leakages to react quickly and to prevent any accident. The gas leak detectors are available for the use in industrial and domestic environments with various types and vender. The selection of type of gas detector will depends upon the environment and gas under question. In this project we are proposed to use MQ-6 gas sensor for the purpose stated above. The Structure and configuration of MQ-6 gas sensor is very simple. The MQ-6 is the LPG (Liquefied Petroleum Gas) sensor. It is suitable for sensing LPG which is usually composed of propane and butane. It can sense LPG gas concentrations in the range 200 to 10000ppm. It is composed of micro AL2O3 ceramic tube and Tin-Dioxide (SnO2) sensitive layer as the main sensing media. To interface with the microcontroller it has measuring electrode. A heater is also fixed into a crust. The heater is used to assist the sensor. The MQ-6 has 06 pin. The 04 pins out of 06 are used to transmission of signals and remaining 02 are for heater power supply. The conductive of MQ-6 is different for different gases but is proportional to the concentration gases. Therefore the sensitivity adjustment will be performed prior to its application.

Temperature Sensor

The measurement of the temperature of a machine or environment is also important in order to detection of rising temperature which will be a sign of abnormally. If the temperature of machine goes beyond the limit, it will be a clear indication of a malfunction and appropriate measures shall be immediately imposed on it. Similarly in this project the temperature sensors attached with this project sense the temperature continuously and give signals to microcontroller. When the temperature of environment rises considerably and the microcontroller will turn ON the cooling fans to controls the temperature of that area. The temperature of the area will also be displayed on a large liquid crystal display (LCD) unit along with other important parameters. The functionality of the temperature sensor DS18B20 is that it is interfaced with microcontroller digitally through its digital pin for output signal in the form of digital stream of bits. The DS1820 don’t require any additional external components for it operation as it has built in ADC. Its power supply of temperature sensor DS1820 will be in the range of 03.0 to 5.5V DC. The DS1820 communicates with the microcontroller over a single line i.e. 01-Wire bus. The one-wire technology requires only one data line for communication with any other suitable component or device. The sensor is consisting of three pins, among them the pin 1 of sensor is connected to ground, positive +5v supply is connected to pin 3, and Output pin is 2.

Fire Detection Unit

The Fire detector is used to detect the fire in a particular area. The fire detection unit used in this project will detect the fire flame in the environment of building. The flame detector is a normal sensor which detects the flame or fire. The Responses of flame detector to detect a flame mainly depend on the location of installation in the building. The fire detection unit will sense the flame on fire event and will provide a signal to microcontroller. The microcontroller will does the appropriate action as per programmed logic to turn ON the buzzer and water sprinkler system. The whole flame of fire sensor is custom based. It is designed and developed using the normally available electronics components in electronics workshop or laboratory as shown in the figure below.

|

| Flame Detection Circuit diagram for the safety to Avoid Fire event |

The Flame sensor is a Zener diode IN4148. The working principle of the flame detecting sensor is the thermal triggering i.e. when there is fire and flames the temperature of that areas will goes high which will trigger the sensor. The high temperature will cause the electrons in the junction of zener diode to move. Then the zener diode voltage will be break down and it will start conducting. Then the detection circuit will generate the output signal and it is connected to the microcontroller. The sensitivity of sensor is adjustable using the variable resistors in the circuit.

Load Controlling Unit

The controlling unit of this project is an important part of the project where various loads are connected with microcontroller using the suitable relays. The beauty of the load controlling circuit is that here each load is controlled individually. The load attached with microcontroller is turn ON or OFF meeting the specification condition by microcontroller. The relay driver circuit includes the use of opto-couplers and Darlington transistors. The relay is an electronics device consisting of a coil. The relays usually have with three contacts named Normally Connected (NC) points, Normally Open (NO) points, and a Common (COM) point. It is used to operate a load which is drawing larger current and work on high voltages therefore proper isolation is provided between the microcontroller and the load devices.

keyword research:

What are the application of microcontroller in industrial automation?

How microcontroller can be used for automation and control applications?

What are the microcontroller applications in industrial instrumentation devices?

Which microcontroller is used in automation?

How microcontroller are used in automation?

What microcontroller is used in home automation?

What are 4 applications of microcontroller?

What are five devices that use microcontroller?

home automation system project using microcontroller pdf

home automation using bluetooth project report pdf

home automation using 8086

bluetooth based home automation system using cell phone

home automation system pdf

home automation using bluetooth hc-05

home automation project pdf

home automation using smartphone

What is the safety of machine?

What is the importance of safety in machines?

What are the 10 safety precautions use in machine shop?

What are the safety features of electrical appliances?

machine and equipment safety

machine safety pdf

5 importance of machine safety

machine safety rules and regulations

what is machine safety

ilo recommendation for work equipment and machinery

20 safety measures of machine safety

machinery hazards and control measures

No comments:

Post a Comment

Please ask if you have any question regarding the programming of MCU, or have any problem in development of your electronics project. microcontroller51.blogspot.com